Produktdetails

Zertifizierung: ISO9001: 2008

Zahlungs- und Versandbedingungen:

Mindestbestellmenge: 1 Satz

Preisverhandlung

Verpackung Details: holzkiste

Lieferzeit: 15 Werktage

Versorgungsmaterial-Fähigkeit: 2000 Sätze

detaillierte Produktbeschreibung

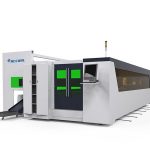

| Produktname: | Faserlaser-Schneidemaschine | Lasertyp: | Faserlaser |

|---|---|---|---|

| Laserleistung: | 500 W, 800 W, 1000 W | Arbeitsbereich: | 3000 * 1500 mm |

| Name: | Cnc-Faserlaser-Schneidemaschine | Merkmal: | Stable Performance, High Efficiency And Low Cost. |

Features Metal Cutting Machine Fiber Laser

1. Laser

Adopting the world’s top fiber laser, stable performance, high efficiency and low cost.

Adopting the world’s top fiber laser, stable performance, high efficiency and low cost.

2. Mechanical structure

With double drive closed-loop structure displacement, Y direction has a strong driving force and high speed, which can give full play to the high speed characteristics of fiber laser.

After two times of aging treatment, the structure of bed body is strengthened to ensure the stability and precision of bed body for a long time.

With double drive closed-loop structure displacement, Y direction has a strong driving force and high speed, which can give full play to the high speed characteristics of fiber laser.

After two times of aging treatment, the structure of bed body is strengthened to ensure the stability and precision of bed body for a long time.

3. Control system

By using open CNC system provided by the top suppliers and integrating the company experience in laser industry for many years, the man-machine interface is so simple and more convenient to operate.

By using open CNC system provided by the top suppliers and integrating the company experience in laser industry for many years, the man-machine interface is so simple and more convenient to operate.

4. Follow-up cutting head

By using the follow-up cutting head of international famous brand, the laser is always in the focus position, can ensure the cutting effect.

By using the follow-up cutting head of international famous brand, the laser is always in the focus position, can ensure the cutting effect.

5. Metal nesting software

The optimized software algorithm can save the material to the maximum extent. Integrated a variety of specialty metal cutting technology such as common edge,bridge and micro connection,the difficulty of operation is reduced, so that improves the material management function, make full use of waste materials and meet the management needs.

6. Auxiliary air blowing system

System combines high and low voltage conversion gas path and three gas source structure composed of high pressure air, nitrogen and oxygen, so customers can select the auxiliary gas according to the processing quality requirements and cost.

7. Lubrication system

The whole machine is equipped with lubrication system, which reduces the wear of moving parts and ensures the movement speed of the whole machine.

8. Editing system

The software supports the input and output of the general CAD format file (PLT, DXF, DST, AI, BMP, etc), as well as graphics editor (zoom, rotate, array, etc)function.

The optimized software algorithm can save the material to the maximum extent. Integrated a variety of specialty metal cutting technology such as common edge,bridge and micro connection,the difficulty of operation is reduced, so that improves the material management function, make full use of waste materials and meet the management needs.

6. Auxiliary air blowing system

System combines high and low voltage conversion gas path and three gas source structure composed of high pressure air, nitrogen and oxygen, so customers can select the auxiliary gas according to the processing quality requirements and cost.

7. Lubrication system

The whole machine is equipped with lubrication system, which reduces the wear of moving parts and ensures the movement speed of the whole machine.

8. Editing system

The software supports the input and output of the general CAD format file (PLT, DXF, DST, AI, BMP, etc), as well as graphics editor (zoom, rotate, array, etc)function.

Hauptkonfiguration

| Artikel | Name | Menge | Marke |

| Laser | 800W Faserlaser | 1 SET | Maxphotonics |

| Schneidkopf | Spezialschneidkopf | 1 SET | RayTools BT (Schweiz) |

| Maschinenbett | 1 SET | China | |

| Präzises Rack | 1 SET | TAIWAN DINSENSE | |

| Maschinenkörper | Präzise Linearführungsschiene | 1 SET | TAIWAN HIWIN / TAIWAN shac |

| X, Y Achse Servo und Treiber | 1 SET | LETRO | |

| Reduziersystem | 1 SET | TAIWAN DINSENSE | |

| Regler | 1 SET | FRANKREICH Schneider | |

| Maschinenbett Zubehör | 1 SET | China | |

| Digitales Schneidsystem | Steuerungssystem | 1 SET | Shanghai cypcut / Shanghai Empower |

| Zubehör | Chiller | 1 SET | Teyu |

| Abfallrecycling-Ausrüstung | 1 SET | China |

Anwendung von Schneidemaschine Faserlaser

Anwendungsmaterialien: Faserlaser-Schneidausrüstung ist für das Metallschneiden mit Edelstahlblech, Flussstahlblech, Kohlenstoffstahlblech, legiertem Stahlblech, Federstahlblech, Eisenblech, verzinktem Eisen, verzinktem Blech, Aluminiumblech, Kupferblech, Messingblech geeignet , Bronzeplatte, Goldplatte, Silberplatte, Titanplatte, Metallblech, Metallplatte, Röhren und Rohre, etc.

Anwendungsindustrien: Faserlaser-Schneidemaschinen werden häufig in der Herstellung von Werbetafeln, Metallbuchstaben, LED-Buchstaben, Küchenartikeln, Werbebuchstaben, Blechbearbeitung, Metallkomponenten und -teilen, Regalen und Schränken, Metallhandwerk, Metallartikeln, Aufzügen eingesetzt Plattenschneiden usw.

500w fiber Speed for example

| Material | m / min |

| kohlenstoffstahl 1mm | 8 |

| Kohlenstoffstahl 2mm | 4.2 |

| Kohlenstoffstahl 3mm | 2.1 |

| kohlenstoffstahl 4mm | 1.2 |

| Edelstahl 1mm | 7.2 |

| Edelstahl 1,5 mm | 3 |

| Edelstahl 2mm | 1.8 |

| verzinktes Blech0,8mm | 5 |

| verzinktes Blech1,2mm | 2.6 |

| verzinktes Blech1,5mm | 1.8 |