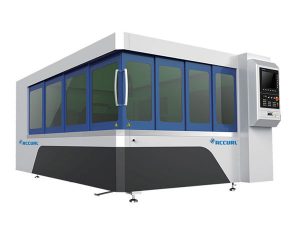

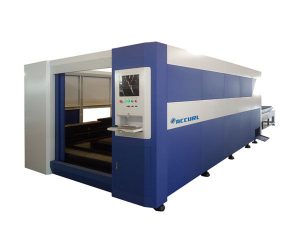

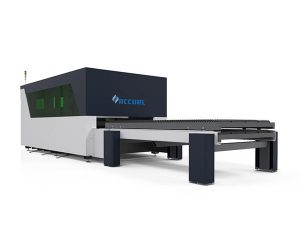

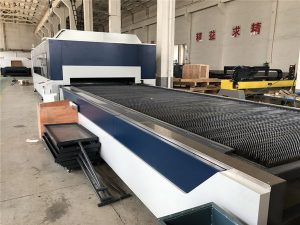

5-Achsen-Laserschneidanlage

CNC precision Laser cutting is a very cost-effective method for manufacturing orders made from sheet metal. Utilising 5 axis of movements enables our machine to cut any profile in any angle, giving freedom to manufacture a wide variety of components. CNC laser cutting technology, which stands for ‘computer numerical control’, uses a LASER programmed by a computer to cut materials. ACCURL customers benefit from the CNC Laser cutting process through high precision part production, reduced cost and faster job delivery.

Laser cutting does not deform the part. The 5-axis laser cut is better and the results are more accurate and consistent. This is ideal for robotic welding. Laser is suitable for all thicknesses including thin walled tubes which are easily deformed during traditional operations.

Copper, aluminium, brass, mild steel, stainless steel, galvanised… The system is equipped with a fiber laser to process any type of metal with maximum efficiency and excellent cut quality every time.

Cutting, piercing, punching, milling, deburring: these operations are traditionally performed in sequence one after the other. The laser does them all together in a single automated operation.

Obtaining the finished part without creating ‘work in process inventory’ is a huge advantage.

Production is simplified, material handling costs are cut and the floor space needed for storage is eliminated.